Capacity

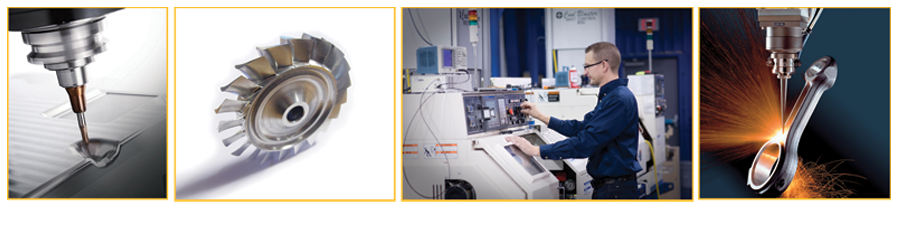

GMC is always looking for new challenges and has the capabilities to accomplish these challenges with a focus on precision, and punctuality. GMC possesses state-of -the art equipment and unmatched technical expertise. Our staff dedicated themselves to total customer satisfaction for each and every job, all while striving to exceed customer expectations.

Our processes have been developed to ensure a seamless transition throughout each phase. From design to delivery, we have the ability to exceed customer expectations.

With the capabilities of Master CAD/CAM system and a ISO Certified Quality System, we are able to manage the design as well as engineer, manufacture and assemble precision components for a wide variety of diverse markets. We are also able to meet the unique specifications and delivery requirements of our customers. We have a competitive cost structure that initially attracts many customers but our customers STAY because of our unparalleled service and attention to their needs.

GMC has the ability to design and manufacture custom tooling and featuring on site. This has proven to offer infinite operational process possibilities. This feature aids in our goal of exceeding our customer's expectations and their overall satisfaction. GMC is committed to continually placing itself on the competitive edge of precision manufacturing.

Our customers can be assured that all documentation will be in order, and continuous improvements will be at the top of all management reviews. The Quality Department has capable equipment that provides customers with the required data that includes: PPAP, APQP, 1st Article Reports, In-Process Inspection Data, Final Inspection Reports and SPC requirements as specified. It also assures internal adherence to our quality manual as well as our stringent quality goals.

GNC places great care in respecting all of our current and potential customer's confidentiality and proprietary concerns.